Lean Automation: Key to Smart Operational Workflow

Lean manufacturing goes back several decades, well before people started using Japanese concepts such as Muda, Muri, Mura, Kaizen etc. The year was 1913 when Henry Ford gave the world the production line, the spine of every manufacturing industry even today. This system was very effective in reducing manufacturing time and throughput, but it was not without its flaws. For example, Ford hadn’t considered the impact of waste accumulation while developing the mass assembly manufacturing system. The concept of design for manufacture was then developed to compensate for wastage generated by shortcomings in Ford’s plan, this involved standardizing parts and tolerances which widely allowed interchangeability of parts.

Researchers believe that the next generation of the production system can be a combination of lean production and robotic production. The cost of applying industrial robotics is often a potential barrier for many companies and with lean concepts the expenditure and advantages of robotic production could possibly be justified. An organization that introduces the highest number of products in less time with the lowest overheads in the market will become the strongest competitor and therefore, many of the organizations adapted lean manufacturing methods. But, the question for engineers in a lean production environment is:

-

What absolutely must be automated?

-

What in the process of production does not need automation?

Manufacturers are now into highly intricate and diversified manufacturing processes. The competitive pressure led them on trying too much for too less. But, the true spirit of lean manufacturing concept varies from production to operation. In this blog, we are about to understand the various aspects of lean manufacturing and how it can help automation robots achieve its true efficiency.

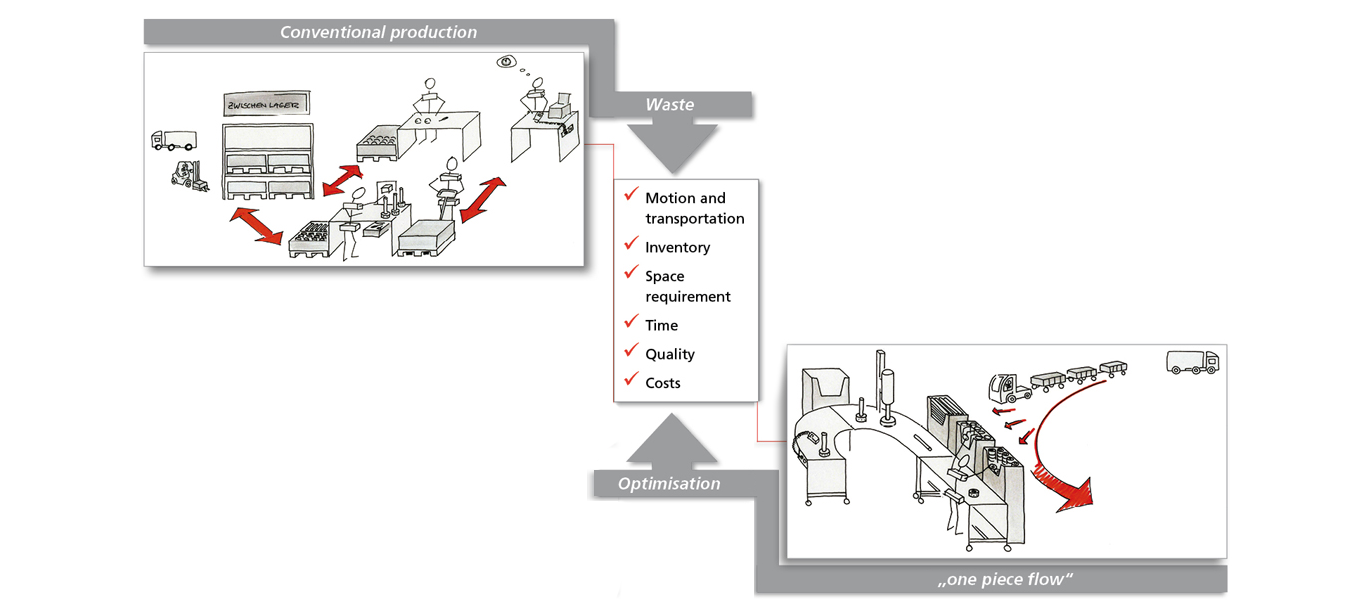

Since we are in the 21st century, lets talk about automation and how it can help in lean manufacturing. In the current scenario waste does not have to be restricted to materials used in manufacturing, it can also include other factors such as finances, floor space or even unproductive labour, basically anything that reduces your throughput. So, lets dive into the world of lean automation and how it can help improve your throughput. A point to be kept in mind while running scenarios for lean automation is that, lean automation is employing the right number of smart devices on line for faster production, lower inventory levels, simplifying the operation and eventually increasing the output. You don’t need 100% automation to achieve this.

1. Identify the wastage

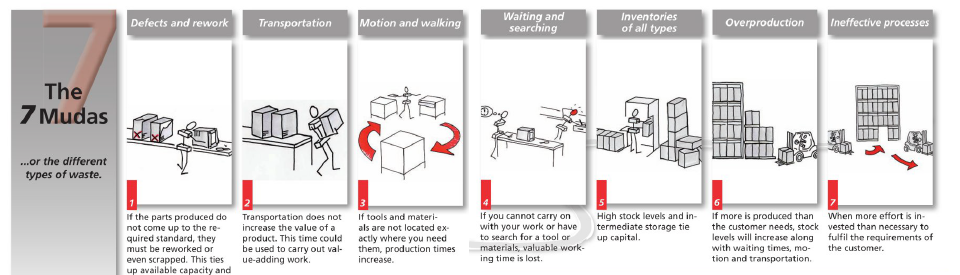

Japanese management philosophy defines 7 types of wastage – Defects, Transportation, Motion, Waiting, Overstocking Inventory, Overproduction, Ineffective production processes. Wastage in today’s time and age usually occurs from quality issues that arise during manufacturing, leading to reworks and remanufacturing – both of which cost money. The best way to fix this issue is to automate repeatable processes and use smart guidance systems for the ones that you don’t. A good example of this is the Pick to Light system which give step by stem guidance to the technician, thereby simultaneously taking care of quality and assembly. More over such systems can now be integrated into ERP systems, thereby allowing you to monitor your process closely, predict roadblocks and prepare for unusual spikes in demand.

2. Utilizing your floor space

Japanese management philosophy defines 7 types of wastage – Defects, Transportation, Motion, Waiting, Overstocking Inventory, Overproduction, Ineffective production processes. Wastage in today’s time and age usually occurs from quality issues that arise during manufacturing, leading to reworks and remanufacturing – both of which cost money. The best way to fix this issue is to automate repeatable processes and use smart guidance systems for the ones that you don’t. A good example of this is the Pick to Light system which give step by stem guidance to the technician, thereby simultaneously taking care of quality and assembly. More over such systems can now be integrated into ERP systems, thereby allowing you to monitor your process closely, predict roadblocks and prepare for unusual spikes in demand.

The one-piece flow is an application of lean manufacturing techniques offered by Phoenix Mecano India Pvt. Ltd.

An extensive range of conveyors are available with Phoenix Mecano India Pvt Ltd. which will allow you to move your material in any direction at very high speeds.

3. Manage your inventory.

Inventory management is key to achieving the best ROI from your operations. Unused raw material in your inventory is an expense while finished goods in inventory is just a cost that you’ve incurred in the guise of your overheads. Concepts such as “Just in Time” (JIT) manufacturing allows you to avoid this blow to your operations but requires meticulous planning and optimum flow of materials within the production line. A wide range of solutions such as FIFO racks and material conveyors allow you to do so. FIFO racks allow you to maintain the flow of materials at workstations while conveyor systems allow you to quickly move material around. Conveyor systems can be easily configured to suit your bespoke needs, even a simple roller conveyor with lifting columns can be used to speed up your line. Effective warehouse management not only allows smoother production but also ensures on-time delivery of your products to your customers.

Not a big fan of all this electric wizardry? Then the answer to your problem lies in Karakuri, the age-old Japanese art of automating purely using mechanical designs. The basic concepts of conversion of potential energy to kinetic energy, gravity and inertia are used to design these systems.

Phoenix Mecano India Pvt Ltd with its wide range of aluminium profiles, conveyor systems, linear technology, pipes and joints provide turnkey solutions for optimizing your operations.